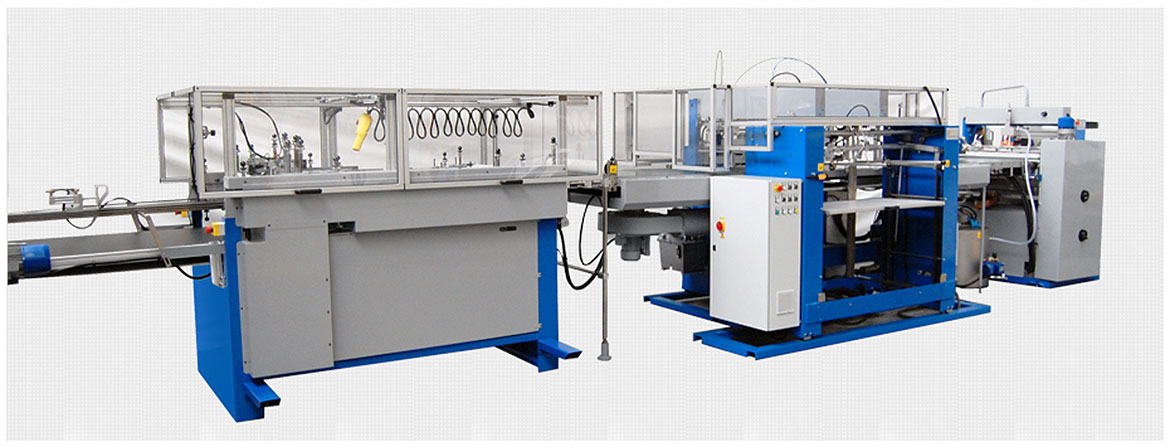

SLC-830 CASEMAKER

SLC-830 Features

- Less than 30 minute Changeovers

- Variable frequency drives

- State of the art PLC’s

- Runs varied substrates

- Economical

- Quick clean up

- Modular in design

- Up to 42 cycles per minute

- Control operations from any PLC

- Photoelectric Registration ±0.5 mm

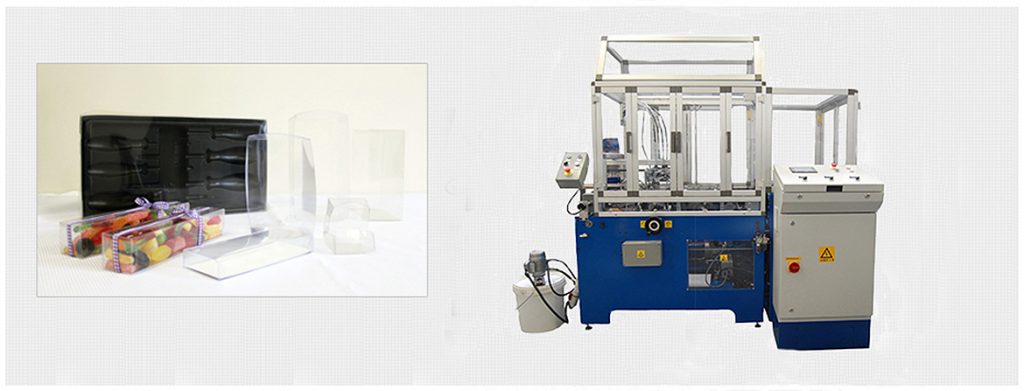

Produce High Quality ...

- Office Files

- Puzzles

- Photo Album Covers,

- Ring Binders

- Game Boards

- Point-of-Purchase Displays

- Book Covers

- Lever arch Files

- Calendars

…

Watch It In Action

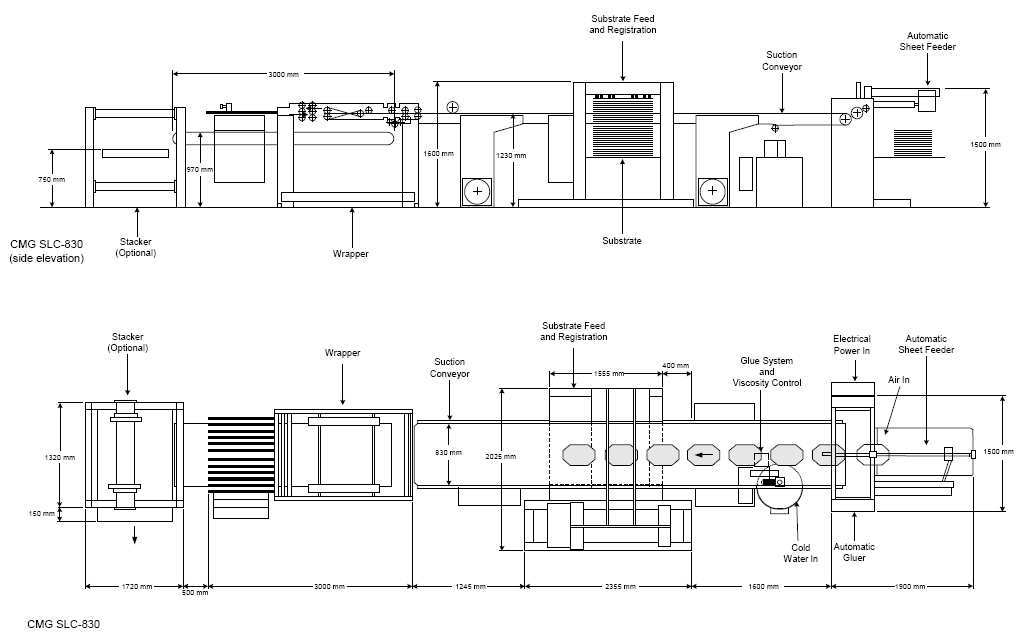

Specifications

Size Range:

Label Size: Minimum 230 mm X 280 mm* Maximum 820 mm x 1230 mm*

Thickness: 80 – 130 g/m². From very light paper to light weight board. Consult sales representative.

Substrate Size: Minimum 200 mm x 250 mm* Maximum 800 mm x 1200 mm*

Thickness: Up to 4mm thick

*Minimum/Maximum sizes are guidelines only. Consult Sales Representative.

Operators Needed:

One operator and one material handler.

Construction Materials:

SHEET MATERIAL: Printed paper, embossed paper, coated paper, backed vinyl, cloth or tyvek. SUBSTRATES: One piece, two piece or prejoined substrates. Chipboard, corrugated board, wood, masonite, plastic or other stiff substrates.

Glue Capacity:

75 liters (19.81 gallons) for hot animal glue.

System available for cold glue.

Registration Accuracy:

Up to ± 0.5 mm at registration point.

Spotting Range:

From 10 mm inside the substrate edge for inside lining to as much as 25 mm outside the substrate edge.

Standard Equipment:

Automatic sheet gluer, suction conveyor belt, glue system with glue viscosity control pumps, automatic substrate feed and registration module, combining rolls.

Optional Equipment:

Oversize substrate, stacker, wrapper module

Energy Requirements:

ELECTRICAL:

230 V, 60 Hz, 20 kva or

380 V, 50 Hz, 20 kva

Supplied as standard.

AIR: 700 L/min @ 5.6kg/cm2 (6 Bar)

Shipping:

WEIGHT: Approximately 2925 kg; skidded